Syrup Filling Equipment, Syrup Filling Capping Machine Line

Package size per unit product 120.00cm * 100.00cm * 200.00cm Gross weight per unit product 1000.000kg Syrup Filling Equi

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ZS-2 |

| Automatic Grade | Automatic |

| Material Type | Liquid |

| Filling Valve Head | Multi-Head |

| Feed Cylinder Structure | Single-Room Feeding |

| Dosing Device | Plunger |

| Filling Principle | Piston Filling |

| Packaging Container Lifting Structure | Pneumatic Lifting |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Composite Materials |

| Applicable Liquid | Viscous Liquid |

| Filling System | Piston Cylinder + Servo Motor |

| Control System | Touch Screen + PLC |

| Equipment Type | Linear Type |

| Filling Speed | 400-3200bph |

| Transport Package | Wooden Case |

| Specification | outer frame: SUS304 material |

| Trademark | Yushun |

| Origin | Qingzhou City |

| Production Capacity | 100pieces/Year |

Packaging & Delivery

Package size per unit product 120.00cm * 100.00cm * 200.00cm Gross weight per unit product 1000.000kgProduct Description

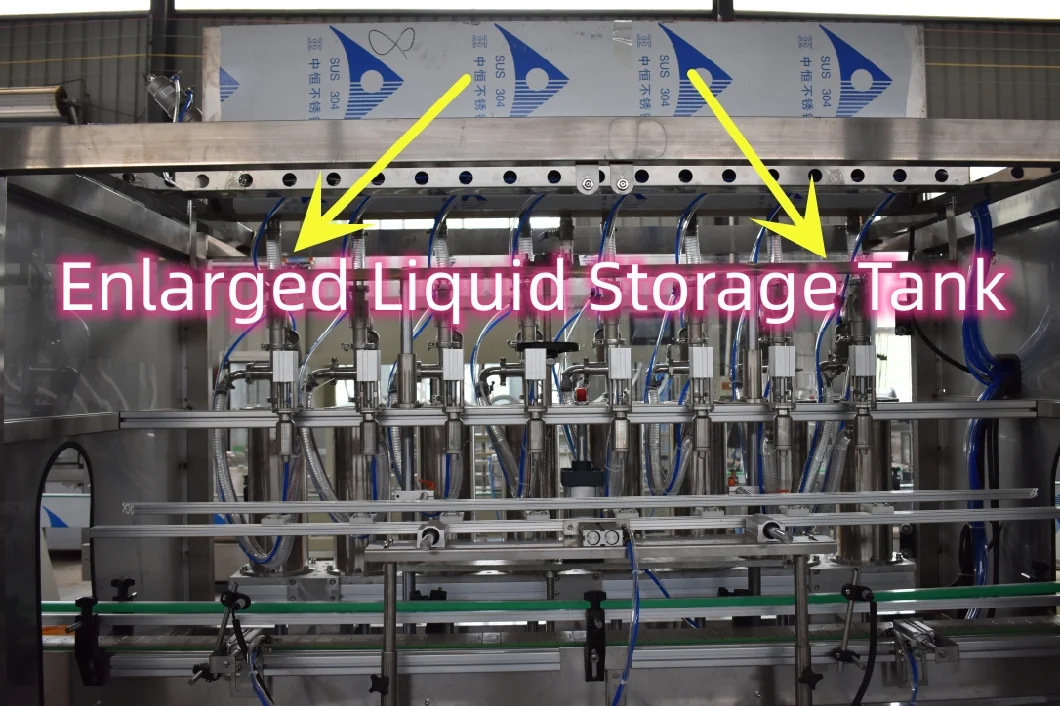

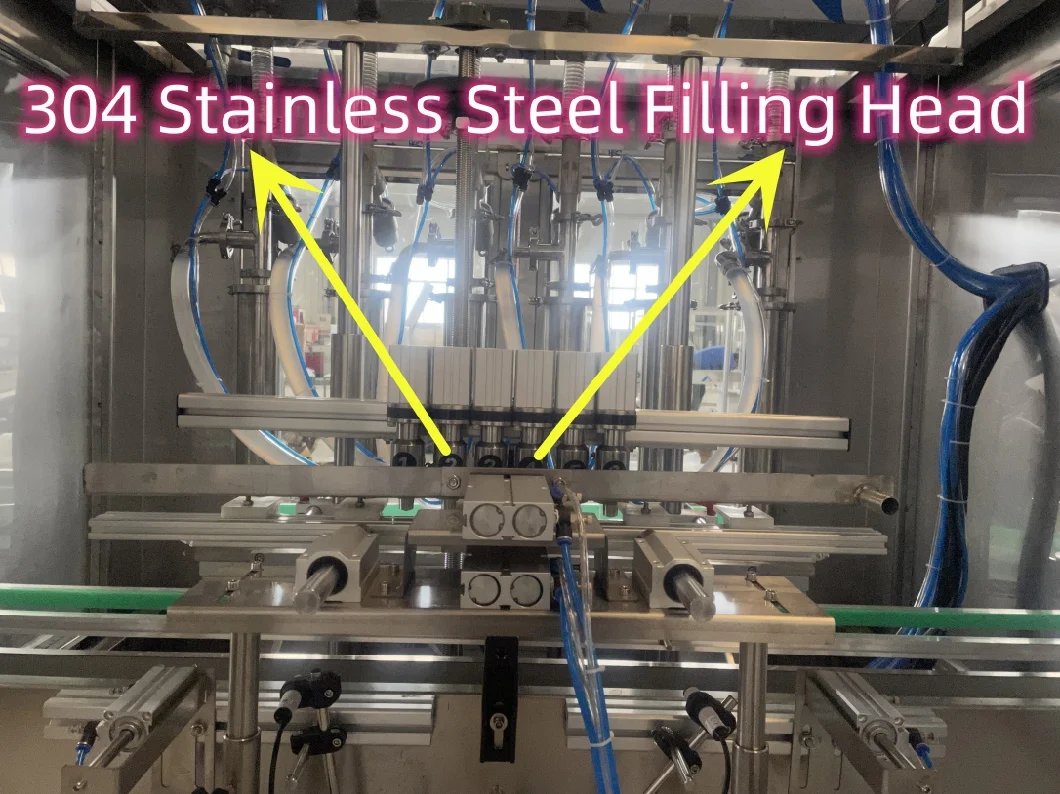

Syrup Filling Equipment, Syrup Filling Capping Machine Line Equipment Photo

| Filling Application | Viscous Liquid |

| Applicable Bottle | Glass Bottle, Plastic Bottle |

| Measurement Error | ±1mm (500ml) |

| Filling Speed | 4 heads 800-1000bph6 heads 1200-1500bph8 heads 1600-2000bph12 heads 2400-3000bph |

| Filling Range | 30-5000ml (Customized) |

| Filling Heads Number | 4, 6, 8, 12 |

| Applicable Bottle Height | ≥40mm |

| Applicable Bottle Diameter | ≥15mm |

| Automatic Grade | Fully Automatic |

| Equipment Type | Linear Type |

| Approximate Size | 1600×1000×2200MM (Customized) |

FAQ

1.Are you manufacturer or trader ?We are manufacturer, we have more than 10 years' manufacturing experience on this field.2.Where is your factory located ?Our factory is located in Qingzhou City, Shandong Province, China.3.Can you test my bottles, caps and labels on your machines before my placing the order ?Yes, if you send us your bottles, caps and labels via international express, we will use your bottles, caps and labels to have a test on our machines and take a video for your reference, if you are satisfied with the test video, you can place the order by then.4.What are the payment terms which you accept ?The payment terms which we accept are T/T (Telegraphic Transfer), PayPal or Western Union.5.What are the delivery terms which you accept ?The delivery terms which we accept are FOB, CIF or EXW.6.Are all your machines customized ?Yes, all our machines are customized based on your bottles, your caps and your labels.7.Can we have a layout drawing ?Yes, we will make a layout drawing for your reference, it will need you to tell us the max. available length and the max. available width of your workshop in which you are ready to put the bottling line.8.Are the directions of the machines customized ?Yes, the directions of the machines can be from left to right or from right to left.

Related Products

-

![Factory Low Price Semi Automatic Liquid Water Drinking Spice Oil Soy Sauce Milk Vinegar Jam Jelly Shampoo Cup Bottle Filling Packing Machine]()

Factory Low Price Semi Automatic Liquid Water Drinking Spice Oil Soy Sauce Milk Vinegar Jam Jelly Shampoo Cup Bottle Filling Packing Machine

-

![12000bph Pet Bottled Beer Bottling Machine]()

12000bph Pet Bottled Beer Bottling Machine

-

![Fully Automatic Bleach/Preservative/Chemical Liquid Filling Machine]()

Fully Automatic Bleach/Preservative/Chemical Liquid Filling Machine

-

![Paixie Automatic Bottle Alcoholic Beverage Whisky Aseptic Food Oil Wine Processing Machinery Paste Filling Machine]()

Paixie Automatic Bottle Alcoholic Beverage Whisky Aseptic Food Oil Wine Processing Machinery Paste Filling Machine